Aluminum Casting Techniques: a Deep Study Products and Techniques for Success

Aluminum casting methods play a crucial role in manufacturing. Numerous approaches exist, each fit to various applications and demands. Sand casting is preferred for bigger parts, while die casting is recognized for its precision in high-volume manufacturing. Financial investment casting offers in-depth styles with superior finishes. Understanding these distinctions can considerably influence project end results. Precision aluminum casting. Picking the ideal approach is not constantly straightforward, leading to essential factors to consider that have to be checked out better.

Comprehending Aluminum Casting: A Review

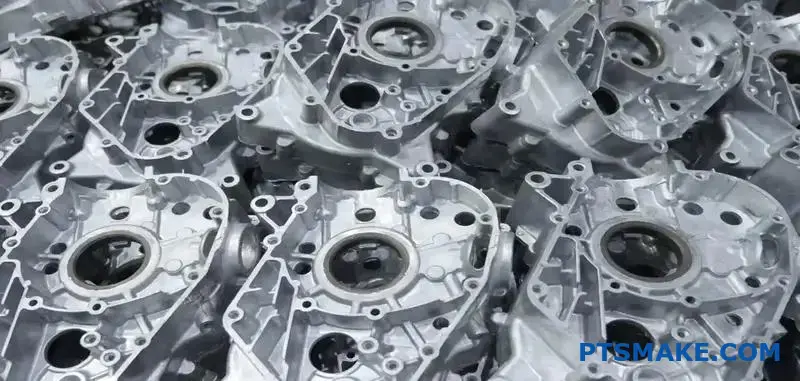

Aluminum casting is an important production process utilized throughout different industries to produce complex elements with high precision. This approach includes pouring molten aluminum into a mold and mildew, enabling it to solidify and take the form of the preferred part. The convenience of aluminum, incorporated with its light-weight and corrosion-resistant residential or commercial properties, makes it a suitable option for applications in automobile, aerospace, and consumer products.

Different casting strategies exist, each fit to details demands and task scales. Elements such as mold materials, cooling prices, and the complexity of the layout play a considerable duty in determining one of the most efficient approach. In addition, the properties of the aluminum alloy utilized can influence the final product's surface, strength, and longevity finish.

Recognizing the basics of aluminum casting allows makers to optimize manufacturing processes, minimize waste, and assurance high-quality output, which is necessary in today's competitive market.

Sand Casting: Applications and techniques

Amongst the numerous techniques used in aluminum casting, sand casting stands apart because of its versatility and cost-effectiveness. This technique involves developing a mold from a blend of sand and binder, which can be shaped to accommodate complex layouts. When the mold is prepared, molten aluminum is poured right into it, enabling for detailed attributes and information to be recorded.

Sand casting is particularly useful for creating large components and low-volume manufacturing runs, making it perfect for auto components, equipment parts, and imaginative sculptures. The method also accommodates an array of aluminum alloys, boosting its adaptability in different applications. In addition, the usage of sand as a mold and mildew material permits easy reclamation and reuse, adding to eco sustainable practices. Accomplishing high dimensional precision can provide obstacles, necessitating competent workmanship and careful control of the casting procedure. In general, sand casting stays an essential method in aluminum factories worldwide.

Die Casting: Precision and Performance

Die casting is an extremely reliable method of creating aluminum parts with remarkable dimensional precision and surface coating. This procedure includes compeling liquified aluminum right into a precisely machined mold under high stress, which allows for intricate styles and very little product waste. The quick air conditioning of the alloy within the mold causes a solidified component that commonly calls for little to no additional machining.

Die casting is specifically useful for high-volume production runs, where uniformity and rate are paramount. It supports the production of complex geometries, making it ideal for numerous applications, including auto, aerospace, and durable goods.

The process can suit different aluminum alloys, enhancing the mechanical residential properties of the ended up products. With its capability to create lightweight yet long lasting components, die casting sticks out as a recommended technique in contemporary production, supplying both precision and performance in aluminum casting.

Investment Casting: Detail and Intricacy

Investment casting, likewise referred to as lost-wax casting, is a accurate and functional approach for generating complex aluminum components. This method is especially valued for its capability to develop intricate geometries and fine information that are often unattainable with other casting approaches. The process begins with a wax pattern, which is covered in a ceramic covering. When the shell hardens, the wax is disappeared, leaving an in-depth mold for aluminum putting.

The advantages of financial investment casting include remarkable surface area coating and dimensional precision, lessening the requirement for substantial machining afterward. It is particularly useful for tiny to medium manufacturing runs where precision is essential. This technique accommodates various aluminum alloys, boosting its applicability throughout industries. Precision aluminum casting. Ultimately, financial investment casting stands out for its capacity to provide both aesthetic appeal and useful efficiency in aluminum components, making it a favored choice for developers and designers seeking complicated services

Choosing the Right Technique for Your Task

Exactly how can more information one identify one of the most appropriate aluminum casting approach for a details project? The selection process rests on numerous crucial elements, consisting of the complexity of the style, the wanted surface finish, and production volume demands. For intricate designs, financial investment casting typically confirms beneficial because of its capability to capture fine details. On the other hand, sand casting might be preferred for larger, less complicated components, offering cost-efficiency and adaptability in production.

Factors to consider concerning tolerances and mechanical residential properties of the last product are important. For high-performance parts, die casting might be the most effective option, as it provides premium dimensional precision and surface high quality. In addition, understanding the product residential properties and compatibility with the selected approach is necessary for making sure the success of the project. Ultimately, a thorough examination of these variables will certainly guide the decision-making procedure, bring about one of the most reliable aluminum casting method for the specific task available.

Regularly Asked Inquiries

What Is the Ecological Influence of Aluminum Casting Methods?

Just How Can I Enhance the Surface End Up of Cast Aluminum?

To enhance the surface area coating of actors aluminum, one can use techniques such as sandblasting, brightening, find out this here and applying finishes. Appropriate mold and mildew style and temperature control additionally considerably enhance the last surface top quality of the cast product.

What Safety and security Precautions Should Be Taken During Aluminum Casting?

Throughout aluminum casting, necessary safety precautions include putting on safety gear, making sure correct air flow, using fire-resistant products, keeping a safe distance from molten metal, and adhering to devices safety and security methods to avoid accidents and injuries.

Just how Do I Troubleshoot Common Casting Defects?

To troubleshoot typical casting flaws, one need to evaluate the mold for damages, examine the alloy composition, check putting temperature, adjust cooling rates, and warranty appropriate venting to lessen air entrapment and boost casting top quality.

What Are the Prices Associated With Different Aluminum Casting Techniques?

The expenses connected with different aluminum casting strategies vary significantly, affected by variables such as product costs, devices, labor, and manufacturing range. Budget factors to consider are essential for picking the most ideal casting technique for certain jobs.

Sand casting is favored for bigger components, while die casting is recognized Visit This Link for its precision in high-volume manufacturing. Amongst the different techniques made use of in aluminum casting, sand casting stands out due to its versatility and cost-effectiveness. Die casting is a highly effective method of producing aluminum elements with exceptional dimensional precision and surface area finish. Financial investment casting, additionally understood as lost-wax casting, is a versatile and precise approach for creating intricate aluminum elements. Just how can one identify the most ideal aluminum casting approach for a specific task?