The Significance of Steel Foundries: A Thorough Introduction of Their Effect On Manufacturing

Metal shops are essential to the production landscape. They transform resources right into parts that offer varied sectors, from vehicle to aerospace. Their expertise in alloy solution and spreading methods guarantees the manufacturing of sturdy parts. The industry deals with obstacles that can improve its future. Comprehending these characteristics reveals the real relevance of shops in economic and technological contexts. What lies in advance for this critical industry?

The Function of Steel Factories in the Production Process

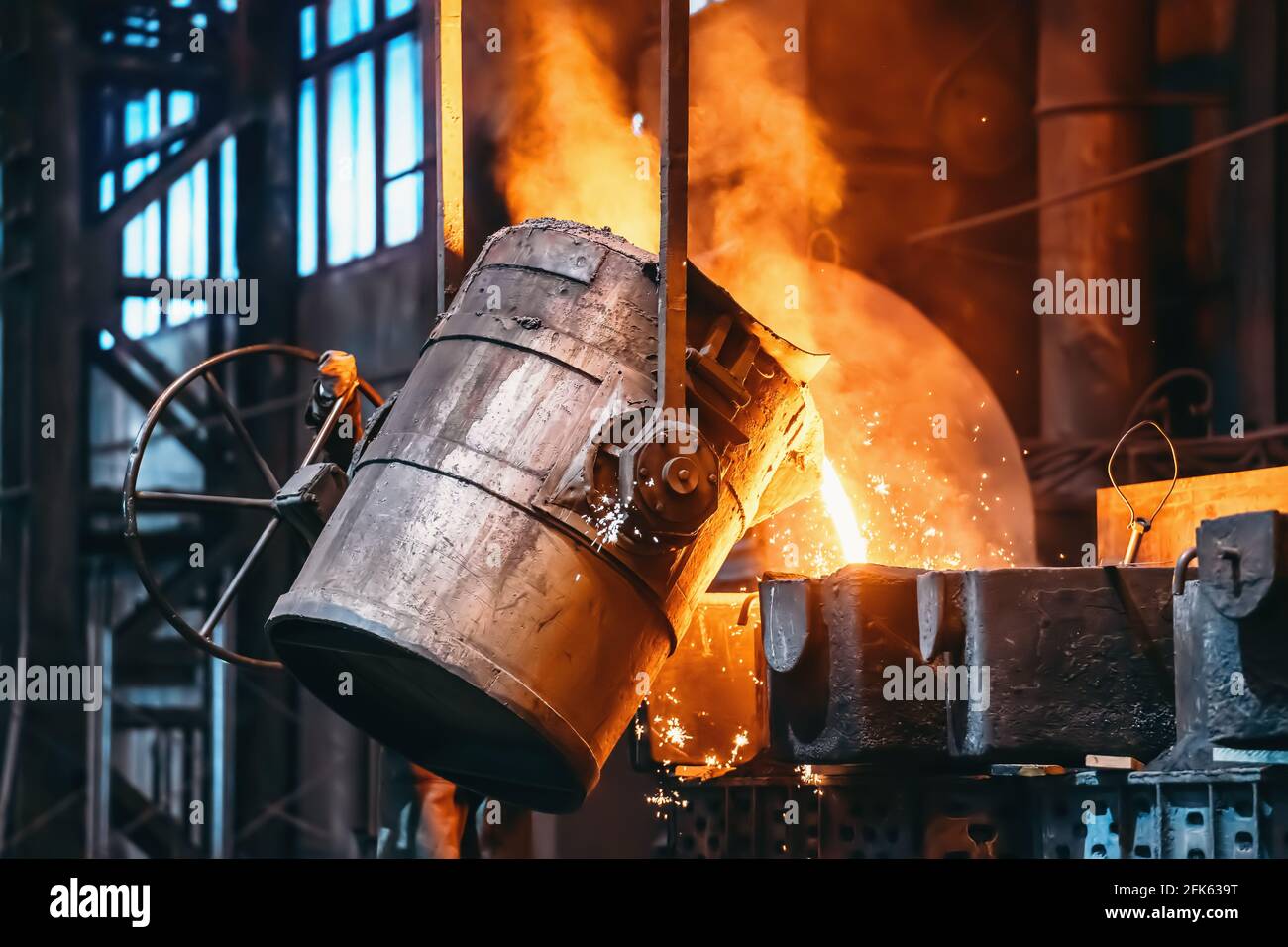

Although usually forgotten, metal foundries play a necessary function in the manufacturing procedure by changing raw steels right into functional components. These facilities specialize in melting various metals, such as bronze, iron, and light weight aluminum, and pouring them right into mold and mildews to produce components for diverse markets. The process starts with the mindful selection of raw materials, guaranteeing that just the finest quality steels are utilized. As soon as melted, the steel handles the shape of the mold, strengthening into elements that fulfill particular design and performance criteria.

Metal shops add significantly to industries like automotive, aerospace, and construction by giving essential parts such as engine blocks, gears, and architectural assistances. Their knowledge in alloy solution and casting methods enables makers to generate detailed styles while maintaining stamina and toughness. Consequently, steel shops not only facilitate the development of crucial components but likewise boost the total performance and capability of modern manufacturing.

Enhancing Production Effectiveness Via Advanced Techniques

Metal factories are progressively adopting advanced strategies to enhance production effectiveness and satisfy the growing needs of numerous industries. The application of automation and robotics has streamlined processes, decreasing manual work and boosting precision in metal casting operations. Additionally, the integration of computer-aided layout (CAD) and simulation software program enables better preparation and optimization of manufacturing workflows, minimizing waste and lowering preparations.

Lean making concepts are also being used to get rid of inadequacies and improve resource use. Foundries are now concentrating on energy-efficient techniques, such as using waste warm recovery systems, which better add to cost savings and environmental sustainability. By accepting these innovative strategies, metal factories are not only improving their operational efficiency however additionally boosting item top quality, leading to greater consumer fulfillment. As industries continue to develop, the capability of factories to adapt to these innovations will be important for maintaining competitiveness in the market.

Innovations in Metal Spreading Technology

As the demand for accuracy and performance in manufacturing grows, advancements in metal spreading innovation are changing the industry landscape. Improvements such as 3D printing and computer-aided layout (CAD) are making it possible for foundries to create complicated geometries with greater accuracy and rate. These strategies minimize material waste and decrease lead times, cultivating a more lasting manufacturing procedure.

Smart shop innovations, including the Web of Things (IoT), facilitate real-time monitoring and information analysis, maximizing production efficiency and decreasing downtime. Jointly, these developments are not only boosting the capacities of metal foundries yet likewise establishing the stage for the future of production, defined by increased dexterity and responsiveness to market needs.

The Economic Influence of Steel Shops on Local and Global Markets

Steel foundries play an important function in forming economic landscapes, both in your area and internationally. They generate considerable work creation opportunities and add to trade and export, boosting overall economic growth. In addition, foundries support regional company ecosystems, promoting interdependent partnerships that improve community strength.

Job Creation Opportunities

Task production in the metal shop market greatly affects both neighborhood and global economic situations. These facilities supply countless job opportunity across different ability degrees, from knowledgeable labor to engineering and administration positions. The demand for steel components in industries such as automotive, aerospace, and building drives the need for a robust workforce. As steel shops expand, they stimulate added work creation in supplementary industries, including transportation, logistics, and supply chain management. Additionally, the economic security given by shop jobs adds to neighborhood communities through increased investing and investment in facilities. On the whole, the steel factory sector's ability to create tasks not just boosts individual livelihoods yet additionally bolsters regional development and strength, showcasing its important role in financial growth.

Export and Profession Contributions

A substantial section of the financial effect created by factories comes from their payments to trade and export. Steel shops play an important duty in supplying elements for various industries, including automobile, aerospace, and building and construction, consequently improving a country's export abilities. By producing top quality spreadings and elements, foundries enable local economic situations to contend on an international range. The export of these products not just raises earnings however also cultivates international collaborations and profession agreements. Furthermore, shops add to a favorable profession balance, which is essential for financial security. The export tasks of steel foundries promote development and investment, ultimately reinforcing their value in both worldwide and neighborhood markets, driving growth and economic resilience.

Citizen Service Support Equipments

While local economic situations usually profit from the visibility of steel foundries, their effect extends beyond simple job development. These centers add considerably to local organization support systems by fostering a network of providers, provider, and supplementary industries. This interconnected ecosystem enhances financial durability, allowing smaller businesses to thrive alongside larger shops. In addition, steel factories commonly engage in area initiatives, investing in regional infrastructure and education and learning, which additionally promotes financial growth. On a more comprehensive scale, the existence of factories can draw in financial investment and skill, strengthening the region's competitive advantage in global markets. Ultimately, the financial payments of steel factories not only develop direct employment yet also grow an encouraging setting for varied local business.

Difficulties Encountering Steel Shops in the Modern Era

As the steel foundry sector advances, it deals with numerous difficulties that endanger its sustainability and competitiveness. One significant issue is the boosting price of basic materials, which directly affects manufacturing expenses. International supply chain interruptions further intensify this issue, making it challenging for factories to preserve constant operations. In addition, labor lacks present a significant hurdle, as experienced workers come to be scarce in a rapidly changing technological landscape.

Moreover, Metal Casting steel foundries have to emulate rigid ecological laws that require higher compliance prices and investment in cleaner innovations. This shift requires factories to adjust rapidly, usually stressing monetary sources.

Competitors from automated manufacturing processes and overseas manufacturing includes pressure, compeling neighborhood factories to introduce or run the risk of obsolescence. Attending to these challenges is important for the industry to thrive in a competitive and significantly complex market environment.

Sustainability Practices in Metal Founding

In feedback to the obstacles faced by the sector, metal factories are increasingly adopting sustainability techniques to boost their functional efficiency and environmental responsibility. These methods consist of the execution of energy-efficient modern technologies, such as electrical induction heating systems, which minimize power intake and greenhouse gas emissions. In addition, several factories are concentrating on recycling scrap steel, lessening waste, and using green materials to minimize their ecological footprint.

Water conservation steps are also being focused on, with systems created to reuse process water, thus lowering freshwater use. Furthermore, factories are purchasing staff member training programs to promote sustainable techniques amongst employees, fostering a society of ecological understanding.

Future Trends in the Metal Factory Industry

Arising innovations and shifting market demands are positioned to improve the steel factory industry in the coming years. Enhancing automation, driven by developments in robotics and expert system, is expected to boost production effectiveness and lower labor expenses. Metal Casting. Additionally, additive manufacturing methods, such as 3D printing, are getting traction, enabling more complicated and customized metal components with lowered waste

Sustainability will certainly also play an important function, with shops adopting greener practices to minimize their ecological effect. The sector is most likely to see a rise in making use of recycled products as raw inputs, lining up with global sustainability objectives.

The need for high-performance and lightweight alloys, specifically in the aerospace and automotive markets, is expected to increase. This development will certainly require recurring investment in research study and development, making it possible for metal factories to adjust and grow in a competitive landscape. Generally, these fads are established to redefine the functional landscape of steel shops.

Regularly Asked Questions

What Sorts of Metals Are Commonly Used in Shops?

Typical steels made use of in foundries consist of iron, zinc, copper, and aluminum. These materials are preferred for their unique buildings, making it possible for diverse applications in markets such as automobile, aerospace, and building and construction, contributing substantially to producing procedures.

How Do Steel Factories Make Sure Item Quality and Uniformity?

Steel shops assure product top quality and consistency through extensive quality control measures, consisting of precise temperature level regulation, product screening, and adherence to sector standards. Routine inspections and experienced workmanship additionally enhance integrity and uniformity in production procedures.

What Precaution Are Carried Out in Steel Foundries?

Metal shops implement safety and security measures such as individual safety equipment, ventilation systems, regular safety training, and rigorous adherence to safety methods to reduce risks. These techniques intend to shield employees and maintain a secure working setting.

What Are the Occupation Opportunities in the Metal Shop Sector?

Occupation opportunities in the metal foundry industry consist of duties such as factory workers, quality assurance assessors, designers, equipment operators, and administration placements. These functions demand numerous abilities, offering paths for improvement and field of expertise within the area.

Exactly How Do Foundries Manage Waste and Recycling of Materials?

Foundries take care of waste and recycling through procedures like recovering sand, melting scrap metal, and utilizing byproducts for energy. These techniques reduce environmental effect while advertising sustainability within the steel spreading market and improving source effectiveness.

Often forgotten, metal shops play a crucial duty in the manufacturing procedure by changing raw metals right into functional components. Metal foundries are progressively embracing sophisticated strategies to enhance manufacturing performance and meet the expanding demands of different sectors. Steel factories play a necessary role in providing parts for different industries, including vehicle, aerospace, and construction, thus boosting a country's export capacities. In action to the obstacles faced by the sector, steel foundries are significantly embracing sustainability techniques to boost their functional performance and ecological responsibility. Aluminum Foundry. Profession possibilities in the steel foundry market include roles such as shop workers, high quality control assessors, designers, maker drivers, and management positions